Centrifugal vs Positive Displacement Pumps: Which Do You Need

Australia’s food and beverage industry relies heavily on positive displacement and centrifugal pumps. Understanding which is best for your production needs is the key to ensuring you get the most out of your equipment without sacrificing quality or efficiency.

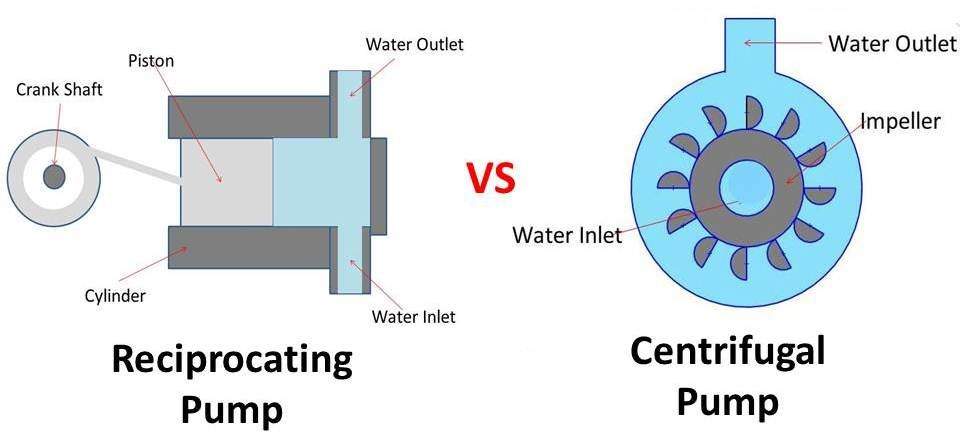

What Is a Centrifugal Pump?

This machine uses centrifugal force to move liquids from one area to another. The key to it all is the centrifugal pump impeller, which spins at high speed and facilitates the movement of liquids. As the fluid passes through the impeller, it creates a vacuum that pulls more liquid in from other areas of the pump. This type of pump is often used for applications requiring low pressure and high flow rates for low-viscosity fluids.

What Is a Positive Displacement Pump?

A positive displacement pump is a machine that displaces liquid from one area to another using an enclosed chamber. The pressure created in the chamber forces the liquid in and out with each cycle, creating a positive pressure. This type of pump is often used for applications requiring high pressure and low flow rates for more viscous liquids such as oil, syrup, or thick food products.

Pros & Cons of A Centrifugal Pump

The main advantage of using a centrifugal pump is that it can typically handle larger volumes of liquid than a positive displacement pump. Additionally, the centrifugal pump impeller runs much more quietly and requires less maintenance than other commonly used options. On the downside, centrifugal pumps are not well-suited for liquids with high viscosities because they cannot create enough pressure to move these thicker liquids effectively.

Pros & Cons of A Positive Displacement Pump

The main advantage of using a positive displacement pump is that it can handle higher viscosities than a centrifugal pump. It can also create higher levels of pressure, making it ideal for applications where the liquid needs to move through narrow passages or at high speeds. The downside is that positive displacement pumps typically require more maintenance than a centrifugal pump and can be loud when running.

How Do I Choose The Right Pump?

Choosing the right pump for your application is essential to ensure optimal performance, so always consider the following factors when making your decision:

- Flow Rate: A centrifugal pump may be the better option if your flow rate is low. If your flow rate is high and you need to move thicker liquids, a positive displacement pump may be the better choice.

- Pressure: A positive displacement pump may be necessary if you need to generate higher pressure for your liquid movement needs.

- Cost: Positive displacement pumps are typically more expensive than centrifugal pumps, so if you are working with a tight budget, the latter may be more cost-effective and less maintenance-heavy.

No matter which type of pump you choose, it’s essential to do your research and select the right one for your production needs. If, after researching, you still aren’t sure which one to go for, don’t hesitate to contact a local supplier or pump specialist for professional advice.

Read Also : Centrifugal vs Positive Displacement Pumps: Which Do You Need