Investigating the Role of Carbon Coated Copper Foil in Battery Technology

Today’s fast-paced and energy-reliant society relies heavily on batteries. Without them, our smartphones, electric vehicles, renewable energy systems and much more would cease functioning entirely; otherwise we would all be left in darkness (quite literally!). Without batteries we would all be back to medieval living!

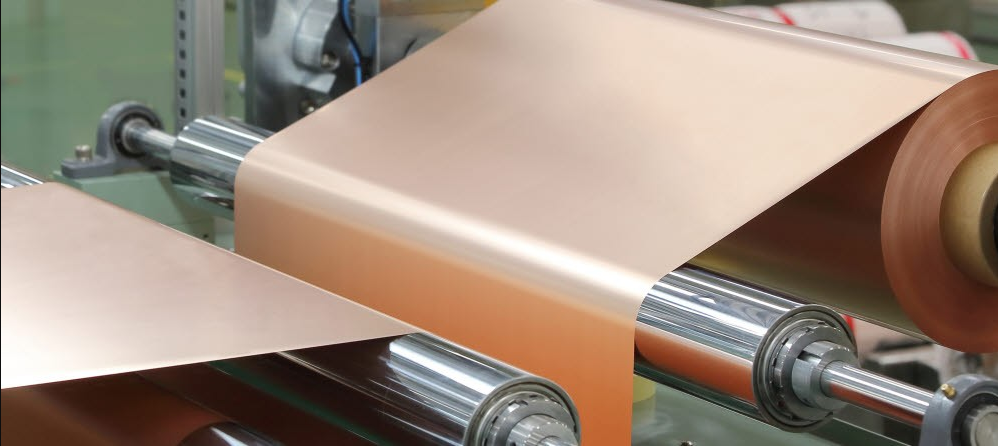

Have you ever found yourself asking how batteries function? Among their key components that is revolutionizing battery technology current collector including carbon coated copper foil – seemingly modest material yet it boasts incredible properties and potential that is making waves in this field of science.

In this blog post, we’ll delve into the fascinating world of carbon coated copper foil batteries and investigate why this essential element has become part of modern batteries. As we uncover its significance and advantages for different battery systems – as well as speculate on future possibilities for further study – join us as we experience this electrifying journey together!

Carbon Coated Copper Foil Has Many Advantages in Battery Technology

Carbon coated copper foil plays a pivotal role in modern battery technology, providing many advantages that make it essential.

Carbon coated copper foil boasts superior electrical conductivity, which allows electrons to flow easily through it for improved energy transfer and battery performance. When electrons flow smoothly through carbon coated copper foil batteries can deliver power more effectively and sustainably.

Carbon coated copper foil also enhances battery stability and longevity by acting as a barrier against corrosion and oxidation, keeping copper intact over time and prolonging battery lifespans. Having such protection means longer-lived batteries with extended lives span.

Carbon coated copper foil enhances battery system safety. The carbon coating acts as a fire-retardant layer that prevents thermal runaway or overheating in battery cells – which is especially crucial in applications where safety is critical, such as electric vehicles or grid-scale energy storage.

Furthermore, this advanced material allows for increased adhesion between active materials in battery electrode layers and current collectors such as copper foils – thus increasing contact between these components and decreasing internal resistance within battery cells and improving overall efficiency.

Carbon coated copper foil offers significantly lower resistivity when compared with aluminum foils typically found in batteries, thanks to its superior electrical conductivity properties. Lower resistance translates to reduced energy losses during charging and discharging cycles–an essential factor in increasing battery efficiency and expanding storage capabilities.

Applications of Carbon Coated Copper Foil in Different Battery Systems

Carbon coated copper foil has become an integral component of various battery systems due to its special properties and superior performance. Let’s explore some key applications where this innovative material has made an impactful statement about their value.

1. Lithium-Ion Batteries: Carbon coated copper foil plays a critical role in lithium-ion batteries as an active current collector, helping ensure efficient electron transfer during charge and discharge cycles, ultimately improving battery performance and stability.

2. Supercapacitors: Copper foil coated with carbon can be utilized in supercapacitors due to its remarkable ability to store vast amounts of energy quickly. Increased surface area allows for faster ion adsorption/desorption rates which improve energy storage capabilities and performance.

3. Fuel Cells: Carbon coated copper foil plays an integral part of fuel cell technology by serving as an essential catalyst support for electrodes. It not only provides excellent electrical conductivity, but it also fosters better gas diffusion through porous electrode structures for increased fuel cell efficiency.

4. Solar Energy Storage: With renewable energy sources becoming more popular, carbon coated copper foils have become a valuable tool in solar batteries for effective energy storage solutions. Their combination of high conductivity and corrosion resistance make them perfect for turning sunlight into electricity efficiently.

5. Electric Vehicles (EVs): For optimal EV batteries performance and safety are of equal concern. Carbon coated copper foils offer low resistance pathways for electron flow inside battery packs to provide optimal power delivery while upholding structural integrity under demanding conditions.

6. Medical Applications: Carbon coated copper foils find applications in medical devices like pacemakers and portable defibrillators due to their long-term reliability requirements.

Carbon-coated copper foil’s versatility enables it to be seamlessly incorporated into various battery systems across industries successfully. From improving lithium-ion battery performance and energy storage in solar cells and fuel cells, carbon-coated copper foil is used in an array of battery applications and solutions.

Future Potential and Research Directions for Carbon Coated Copper Foil

Carbon coated copper foil has become increasingly crucial to battery technology over the past several years, as researchers and scientists explore new opportunities and directions for this innovative material.

One area of emphasis for battery researchers is increasing energy density. By employing carbon coated copper foil, they are able to enhance performance and capacity of batteries, enabling them to store more energy in less space – something which could transform industries such as electric vehicles by either expanding their range or making them more compact.

Researchers are exploring ways to optimize the production process of carbon coated copper foil. By improving production techniques, researchers hope it may be possible to reduce costs and boost efficiency, making these materials more cost-effective for widespread adoption in various battery systems.

Future exploration could include the integration of carbon coated copper foil with other cutting-edge materials, such as graphene or silicon nanoparticles, which may provide further improvements in battery performance and enable next-generation batteries that offer faster charging times, longer lifespans and greater stability.

Conclusion:

Carbon coated copper foil has shown great promise as an enabling factor, due to its flexibility and conductivity properties, in creating flexible wearable batteries with optimal performance that conform to various shapes. Research into flexible wearable batteries continues apace; one such effort has aimed to develop battery packs which conform to different body shapes without compromising performance.

Carbon coated copper foil plays an integral role in battery technology today – yet its potential goes far beyond our understanding. As researchers continue their investigation of its applications and innovate, we can expect breakthroughs to shape energy storage devices across industries worldwide!

Read Also : Investigating the Role of Carbon Coated Copper Foil in Battery Technology