Optimizing Productivity: Exploring the Efficiency of Multihead Weighers in Packaging Processes

Title: Optimizing Productivity: Exploring the Efficiency of Multihead Weighers in Packaging Processes

Abstract: The packaging industry plays a crucial role in ensuring products reach consumers in optimal condition. Efficient packaging processes not only enhance product safety but also contribute to overall productivity. This study focuses on the utilization of multihead weighers, a cutting-edge technology, to optimize packaging efficiency. The research investigates the benefits of multihead weighers, their working principles, and their impact on productivity when compared to traditional weighing and packaging methods. Through a combination of empirical data, case studies, and industry analysis, this research aims to provide insights into the significant advantages of adopting multihead weighers in packaging processes.

- Introduction: In today’s competitive market, optimizing productivity is essential for manufacturers aiming to meet customer demands and enhance profitability. The packaging process is a critical aspect of product delivery, requiring precision and efficiency to maintain product quality and reduce wastage. Multihead weighers have emerged as a technological advancement that offers potential solutions to challenges in the packaging industry. This study aims to explore the efficiency of multihead weighers and their impact on enhancing productivity in packaging processes.

- Multihead Weighing Technology: Multihead weighers are automated systems that employ advanced algorithms to accurately measure and distribute products into packaging units. These machines consist of multiple weighing heads, each with its own load cell, that work simultaneously to optimize the distribution process. The technology ensures consistent weights and minimizes product giveaway, which can lead to significant cost savings.

- Benefits of Multihead Weighers: This section highlights the key advantages of using multihead weighers in packaging processes: a. Speed and Throughput: Multihead weighers can significantly increase packaging speeds, leading to higher throughput and reduced production cycle times. b. Accuracy: The technology’s precision minimizes product variations, leading to more consistent package weights and improved product quality. c. Waste Reduction: By reducing product giveaway and minimizing inaccuracies, multihead weighers contribute to decreased waste and increased overall efficiency. d. Versatility: Multihead weighers can handle a wide range of products, sizes, and shapes, making them suitable for various industries. e. Labor Savings: Automation reduces the need for manual labor in the weighing and packaging process, leading to cost savings.

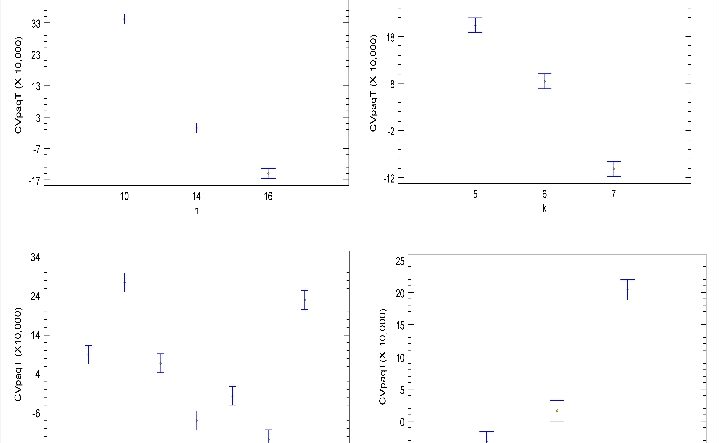

- Case Studies and Empirical Data: This section presents real-world case studies and empirical data comparing the efficiency of multihead weighers to traditional weighing methods. These examples demonstrate the positive impact of multihead weighers on packaging speed, accuracy, and overall productivity.

- Implementation Considerations: To successfully implement multihead weighers, factors such as product characteristics, packaging materials, and production volumes need to be considered. This section provides guidance on how to choose the right multihead weigher configuration based on specific requirements.

- Challenges and Mitigations: While multihead weighers offer numerous benefits, challenges such as initial investment costs, maintenance, and technical expertise can arise. This section discusses strategies to address these challenges and ensure a smooth integration of the technology.

- Future Trends and Conclusion: As technology continues to advance, the packaging industry can expect further innovations in multihead weighing technology. This section discusses potential future trends and concludes by emphasizing the transformative impact of multihead weighers on packaging efficiency and overall productivity.

- References: This section lists the sources and references used in the study, including industry reports, research papers, case studies, and relevant literature on packaging processes and multihead weighing technology.

By exploring the efficiency of multihead weighers in packaging processes, this research contributes valuable insights to manufacturers seeking to enhance productivity, reduce costs, and maintain product quality in an increasingly competitive market.